In the world of packaging and print design, a concept that is vital yet often misunderstood is the dieline. This fundamental element serves a multitude of purposes and is instrumental in creating the final product that fulfills brand visions and consumer expectations. In this blog post, we dive deep into the nuances of dielines, exploring their definition, components, creation, optimization for production, and their critical role in successful packaging design.

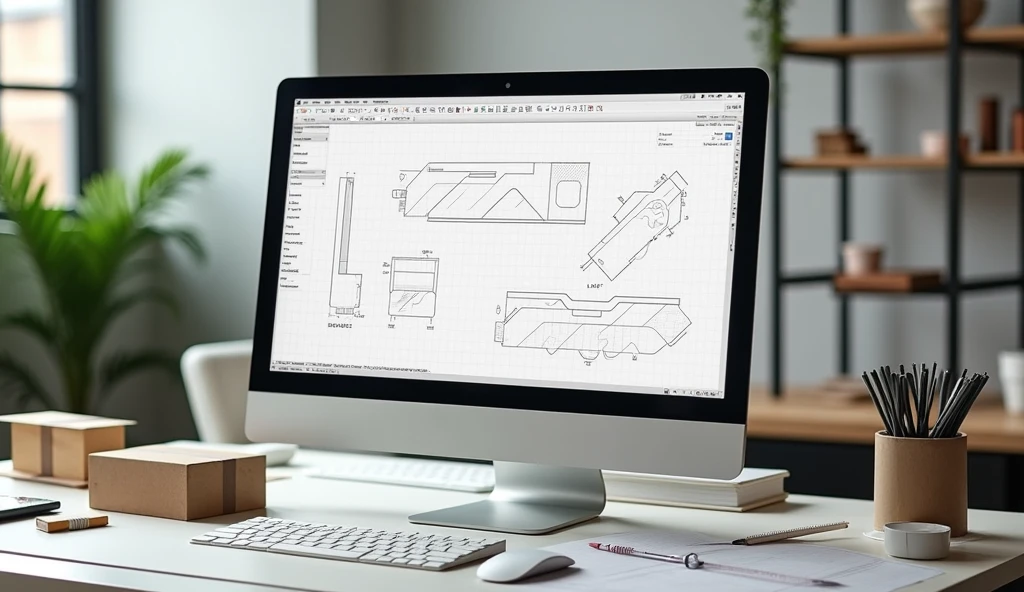

A dieline is essentially a template that outlines cut, fold, and perforation lines for packaging. Think of it as a roadmap or blueprint that guides designers and manufacturers in producing physical items that align with design expectations. It is typically a flattened representation of a package's structure, showing exactly where the cuts and folds will take place.

Dielines fulfill several essential roles:

Some common applications of dielines include:

Dielines are not just simplistic designs; they contain essential elements that ensure proper assembly and functionality. Here are the main components:

Cut lines are defined by solid lines that indicate where the die-cutting machine will slice through the material. These lines are critical for establishing the overall shape of the packaging.

Fold lines, often marked with dashed lines, indicate where the packaging will bend or fold to interlock and create the final shape. This ensures that each panel aligns perfectly during assembly.

These dotted lines indicate areas where the material will be perforated for easy tearing. Commonly found in food packaging, these lines help consumers open packages without any fuss.

Creating an effective dieline involves careful planning and attention to detail. Here’s a step-by-step guide to crafting a high-quality dieline:

Start by determining the dimensions of your product. Accurate measurements are essential as they form the basis of your dieline. You can take apart existing packaging or use wrapping paper to create a prototype.

Once you have your measurements, use graphic design software (such as Adobe Illustrator) to create the dieline. Most professionals prefer vector-based software because it allows for easy adjustments and ensures that the lines remain crisp and clear.

Before moving to production, create a physical prototype using your dieline. This allows you to see how your design will function in real life and enables you to test for any structural weaknesses or design flaws.

Once a dieline is created, the next step is optimizing it for the production process. This phase involves:

Communication is key. Designers should regularly connect with manufacturers to ensure that the dieline meets all technical requirements and production capabilities.

Be mindful of frequent errors, such as incorrect measurements, not accounting for material thickness, or failing to consider the impact of folds. Providing multiple reviews can help catch these mistakes before production.

Always test your prototypes. While a dieline might look perfect on screen, physical testing can reveal issues that need adjustment. Prototyping saves time and helps reinforce the functionality and aesthetic of the final package.

Understanding and correctly implementing dielines is fundamental to the success of any packaging project. They lay the groundwork for design integrity and production efficiency. As brands strive for innovative and high-quality packaging, the importance of effective dieline creation only grows.

As we look towards the future, advancements in design technology are likely to transform how dielines are created. Integrating AI and automated tools will streamline the design process and improve accuracy, enabling designers to push the limits of creativity while maintaining feasibility in production.

What is the difference between a dieline and a mockup? A dieline is a flat layout that shows the cuts and folds for production, while a mockup is a three-dimensional representation of what the final product will look like.

Can anyone create a dieline? While anyone with access to the right tools can create a dieline, it is recommended to consult a designer or a packaging expert for best results.

Why are safety lines important? Safety lines ensure that all necessary design elements are visible and not cut off during the final production, maintaining brand integrity and aesthetics.

By mastering the art of dielines, brands can ensure streamlined production and create packaging that not only protects products but captivates consumers. Understanding this critical aspect of design is key to achieving excellence in packaging and print design.