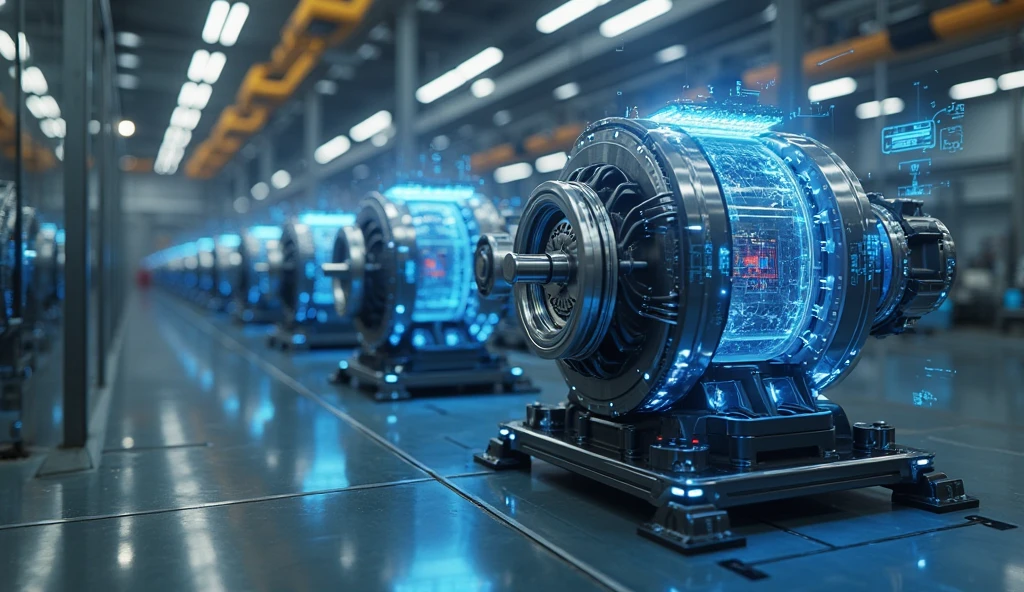

Electric motors are essential devices in modern industry, converting electrical energy into mechanical energy. They play a crucial role in various sectors by providing the necessary power to drive machinery and equipment. The efficiency, durability, and specific applications of an electric motor are highly influenced by its type. For instance, in the manufacturing sector, AC motors are preferred for steady speed operations, whereas DC motors are often used in variable speed applications like in robotics and。consumer electronics. Understanding these differences is vital for selecting the right motor for specific industrial needs.

Alternating current (AC) motors operate using alternating current and magnetic fields to produce motion. They are classified primarily into two types: synchronous motors and induction motors. Synchronous motors maintain a constant speed by synchronizing the rotation of the rotor with the rotating magnetic field of the stator. On the other hand, induction motors, which are more common, generate torque through electromagnetic induction, where the current in the rotor is induced by the magnetic field of the stator without direct electrical connection.

The benefits of AC motors include higher efficiency, reduced maintenance needs, and versatility, making them suitable for various applications. They are extensively used in industrial machinery, HVAC systems, and household appliances due to their robustness and reliability. Additionally, AC motors typically boast lower operational costs over time compared to other motor types. In environments where durability and continuous performance are critical, such as manufacturing plants and large-scale commercial settings, AC motors are the preferred choice. Their ability to handle high loads efficiently results in significant advantages for long-term operation and energy savings.

DC motors operate by converting direct current into motion through electromagnetic principles, making them a crucial component in various technological applications. On a basic level, they use a commutator and brushes to reverse the current direction in the motor's armature, which facilitates the creation of a rotating magnetic field. This process is central to the motor's functionality, enabling it to produce consistent movement from the electricity supplied.

The primary advantages of DC motors include precise speed control and their simple design, aspects that make them ideal for an array of applications. Industries often leverage DC motors for tasks requiring meticulous control and adaptability, such as in robotics, where motor accuracy is paramount, electric vehicles that demand reliable performance, and conveyor systems that benefit from the motor's ease of controlling speed. Their operational simplicity combined with effective performance makes DC motors a staple in these innovative fields.

Synchronous motors operate at a constant speed that is synchronized with the frequency of the AC power supply, making them ideal for applications where speed constancy is crucial. These motors are highly efficient, as they do not experience slip, meaning their rotational speed matches the magnetic field speed exactly. This characteristic is beneficial in industrial settings where consistent speed under varying load conditions maximizes operational efficiency and minimizes downtimes.

Conversely, asynchronous motors, commonly known as induction motors, operate on the principle of electromagnetic induction and inherently exhibit slip, meaning the rotor always rotates slightly slower than the synchronous speed. This slip allows asynchronous motors to adjust energy consumption based on load, making them suitable for applications with varying load demands, such as conveyors or pumps. Their robust construction and ability to handle variable loads with ease makes them a popular choice in various industrial applications.

Both motor types are critical in different manufacturing processes. Synchronous motors are favored in environments requiring precise control and high efficiency, such as electric drives and some renewable energy systems. In contrast, asynchronous motors are widely used in machinery that experiences dynamic loads due to their flexibility and reliability. Understanding the specific advantages of synchronous and asynchronous motors enables industries to optimize performance across applications like conveyor belts, manufacturing lines, and energy systems.

Selecting the right electric motor is crucial for ensuring optimal performance in different applications. Key factors include load requirements, environmental conditions, and adherence to energy efficiency standards. Understanding these elements helps in selecting a motor that can handle the desired workload without excess energy consumption or undue wear and tear. By choosing a motor tailored to specific load demands and environmental challenges, businesses can achieve sustainable performance and longevity in their operational equipment.

Furthermore, evaluating efficiency and performance metrics is vital to ensure the suitability of motors for specific applications. These metrics include torque, speed, and power consumption, which together define the motor's ability to meet operational demands effectively. For instance, torque is critical for applications involving heavy lifting or acceleration, while speed is vital for tasks requiring precision and quick movements. Analyzing these factors helps in selecting a motor that not only meets operational requirements but also aligns with energy efficiency goals, leading to cost savings and enhanced productivity.

The future of electric motors is set to be transformative, driven by current innovations in technology such as advanced materials, sophisticated control systems, and smart technology integration. These innovations are allowing electric motors to become more efficient and adaptable, crucial for cutting-edge applications. For instance, the use of lighter and stronger materials is increasing motor lifespan while reducing energy consumption, and integration with IoT systems is enabling smarter and more responsive control across different applications.

Looking ahead, significant market growth is anticipated, with industry reports forecasting a substantial rise in electric motor usage. According to Market.us, the global electric motor market size is expected to surpass USD 249.6 billion by 2032, with a CAGR of 6.8% from 2023 to 2032. Demand is particularly increasing in sectors such as automotive, aerospace, and renewable energy, where the transition towards sustainable and efficient technologies is gaining momentum. With ongoing technological advancements and a growing emphasis on sustainability, electric motors will play a pivotal role in these industries' futures.

The main types of electric motors are AC motors, including synchronous and induction motors, and DC motors.

AC motors offer higher efficiency, reduced maintenance needs, and versatility, making them suitable for various applications.

DC motors are commonly used in applications requiring precise speed control and adaptability, such as robotics, electric vehicles, and conveyor systems.

Synchronous motors maintain a constant speed synchronized with the AC power supply frequency, whereas asynchronous (induction) motors experience slip and adjust energy consumption based on load.

Factors include load requirements, environmental conditions, energy efficiency standards, torque, speed, and power consumption.