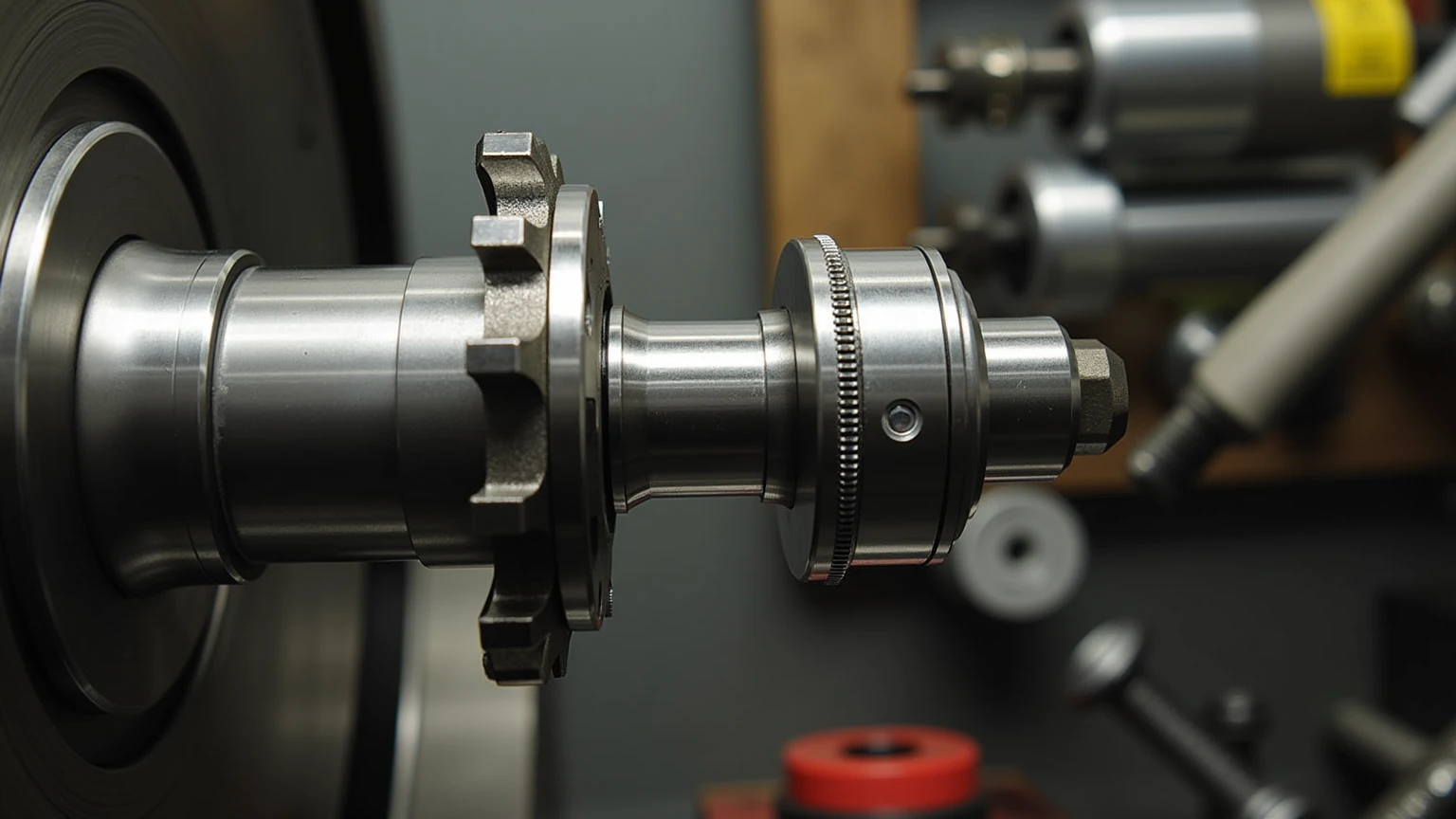

Keystock is a crucial component in machinery, acting as a removable bar used to transmit torque from components like couplings, sheaves, sprockets, and gears to a shaft. It functions by locking a component to the shaft through a corresponding keyway. Keystocks come in various dimensions and shapes, such as square and rectangular forms, with sizes typically ranging from 1/16" to 2-1/2" square. They're available in materials like 1018 carbon steel, stainless steel, and brass, and can be zinc-plated for additional durability.

The importance of keystock lies in its ability to secure rotating elements such as pulleys and gears, effectively preventing slippage and ensuring operational efficiency. By locking these components in place, keystock enhances machinery's performance and longevity. This is particularly vital in applications involving high-speed or high-load operations, where the risk of slippage is increased. Furthermore, keystock contributes to minimizing downtime and maintenance costs, ensuring continuity in industrial operations.

Standard keystock is a fundamental component used in various mechanical systems. Typically, it is available in dimensions ranging from 1/16" to 2-1/2" square, manufactured in materials such as steel, stainless steel, or brass. These bars, often used for their ease of replacement and widespread availability, play a crucial role in securing rotating components, such as gears and pulleys, to shafts. Their standardized sizes ensure consistent performance, making them an ideal choice for general applications across industries.

Step keystock is particularly advantageous in applications that require precise alignment; it features a dual-step design that adapts to mismatched keyways and shafts. This type of keystock is commonly used in industries like automotive and machinery repair, where alignment precision is critical. For instance, it serves well in assembling couplings, gears, and pulleys, fulfilling demands for exact component synchronization and alignment.

Undersize keystock is specifically designed for systems where precise tolerances are of utmost importance. Its dimensions are intentionally smaller, accommodating minute discrepancies within machinery to ensure a snug fit without unnecessary wear. This adaptability is particularly useful for components subject to regular wear and tear. By allowing for subtle movement, undersize keystock prolongs the life of mechanical assemblies, making it a valued choice for high-precision applications.

Machinery keys, a type of keystock, are tailored to fit specific attributes required in mechanical assemblies. Typically made from durable materials like 1018 carbon steel, they serve to lock components securely while permitting axial movement, essential in certain mechanical transmissions. By maintaining a balance between fixation and freedom of movement, machinery keys optimize the function of complex mechanical systems, proving indispensable in diverse engineering applications.

Woodruff keys are noted for their unique crescent shape, which provides a secure grip in confined spaces and reduces the risk of shaft distortion. They are favored in scenarios where a compact and reliable securing method is required—a reason they're extensively used in automotive and aerospace sectors. These keys fit into rounded keyways, facilitating easier assembly and disassembly, which is particularly advantageous in manufacturing settings where time and ease of maintenance are crucial.

Tapered keys are instrumental in applications requiring efficient torque transmission due to their gradually decreasing thickness. This design enables a tighter fit as the key is driven into place, which can adjust to slight discrepancies in the fit, providing enhanced holding strength. Such qualities make tapered keys indispensable in situations necessitating robust torque transfer and precision in fit adjustment, such as in heavy industrial machinery and equipment.

Carbon steel keystock is renowned for its exceptional strength and durability, making it a popular choice in various mechanical applications. Its inherent mechanical strength ensures that it can withstand substantial torque and stress, which is why it is widely used in industries like automotive and construction equipment. Additionally, carbon steel is cost-effective, providing a balance of performance and affordability for manufacturers. Its versatility in both standard and custom applications makes it a go-to material for keystock production, supporting machinery and vehicles in robust operating environments.

Stainless steel keystock offers superior corrosion resistance, a property especially valuable in humid or marine environments. The material's resilience to rust and oxidation makes it indispensable in industries such as marine, food, and pharmaceutical processing where cleanliness and longevity are paramount. Stainless steel keystock is engineered to deliver both strength and sustainability, ensuring long-term functionality even under harsh conditions. This characteristic makes it an essential component in maintaining machinery and facilitating reliable mechanical operations across these demanding sectors.

Brass keystock is appreciated for its excellent corrosion resistance and mechanical properties, particularly under conditions of wear and heat. Its non-sparking quality is beneficial in electrical assemblies, where safety is a top priority. This makes brass keystock an ideal material in sensitive environments like electrical and mechanical assemblies where consistent performance is necessary. Moreover, its ability to conduct electricity effectively ensures that brass keystock remains a preferred option for various industrial applications, combining practicality with safety.

Zinc-plated keystock is distinguished by its enhanced longevity and rust resistance, achieved through a protective zinc coating. This additional layer shields the keystock from environmental elements, ensuring its integrity over time. Such features are particularly beneficial in outdoor and corrosive settings, such as those found in the construction and oil and gas industries. The zinc plating not only prolongs the keystock's lifespan but also reduces maintenance needs, making it a cost-effective choice for applications where longevity is crucial.

Understanding torque requirements is paramount when selecting the appropriate keystock for any project. Torque refers to the twisting force that causes rotation, and selecting a keystock that can withstand the necessary torque is crucial to ensure mechanical reliability and performance. The torque ratings correlate directly with the choice of material and the dimensions of the keystock. For instance, higher torque applications often require stronger materials like carbon steel and larger dimensions to withstand the stress without failure. Thus, it is essential to assess the torque demands of your project carefully to specify an appropriate keystock dimension and material.

Environmental factors significantly influence the selection process of keystock materials. Exposure to moisture, chemicals, or extreme temperatures can impact the durability and performance of the keystock. In environments where moisture is prevalent, such as marine or outdoor applications, corrosion-resistant materials like stainless steel or zinc-plated options are advisable. These materials offer enhanced protection against rust and degradation. Similarly, environments with high chemical exposure might necessitate a material with robust resistance to chemical corrosion. Therefore, evaluating the environment where the keystock will be used allows for selecting materials that provide the necessary longevity and reliability.

The dimensions of a keystock, including its size and shape, are vital for ensuring optimal mechanical performance. Improper sizing can lead to inefficient operation or even mechanical failure, as it might not transmit the torque correctly or securely lock the components in place. When measuring for the correct size and shape, consider both the keystock's width and length relative to the application to ensure a snug fit within the keyway. Accurate measurements are essential, utilizing tools like calipers can help determine exact specifications needed for an effective fit. A precise match between keystock and keyway dimensions is critical for optimal performance and durability.

Keystock is used in machinery to lock components like couplings and gears to a shaft to prevent slippage and ensure efficient transmission of torque.

The types include standard keystock, step keystock, undersize keystock, machinery keys, Woodruff keys, and tapered keys, each serving specific applications.

Material choice impacts the keystock's strength, durability, corrosion resistance, and suitability for specific environments or mechanical demands.

Choosing the correct size involves ensuring it matches the keyway dimensions accurately to transmit torque effectively and securely lock components.