Particle breathers are essential components in electrical systems designed to filter out particulate contaminants. Their primary function is to enhance the efficiency and longevity of machinery by preventing harmful particles from entering the system. These breathers work much like a coffee filter that keeps grains out of the pot, trapping large debris but sometimes struggling with finer contaminants. Typically constructed from materials designed to catch and hold particulates, particle breathers must be effective across various environments.

The mechanics of particle breathers involve materials like steel wool, which is often found in OEM equipment. However, these basic filters may not suffice in challenging environments, as they might permit finer particles through. This necessitates regular maintenance and replacement to ensure optimal protection. According to industry data, significant equipment failures can be attributed to contamination, emphasizing the importance of efficient breather systems in preventing dust ingress and extending the lifespan of electrical systems.

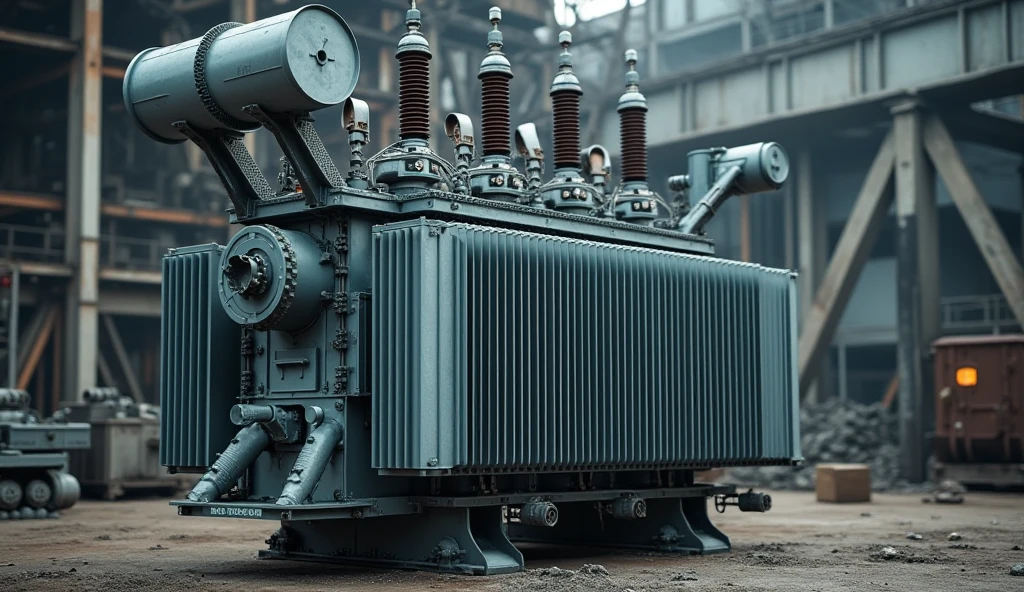

Desiccant breathers offer a more advanced solution for moisture and contaminant control, crucial for protecting sensitive electrical components and transformer oils. These breathers use desiccants such as silica gel to absorb moisture from the air, maintaining low humidity levels and preventing moisture-induced issues like corrosion and viscosity changes. This is vital as over 70% of equipment failures are linked to contamination, with 20% due directly to corrosion.

Studies demonstrate that moisture control significantly enhances system reliability and performance. Desiccant breathers function by filtering incoming air through a solid particle filter and silica gel layer, thus ensuring that only clean, dry air enters the system. This prevents moisture from causing equipment degradation and extends the life of the machinery. Hence, for environments prone to moisture, such as coastal or humid areas, desiccant breathers are indispensable for preserving electrical system integrity.

Smart breathers in transformers offer exceptional moisture elimination, utilizing advanced materials and designs to absorb moisture effectively. By maintaining lower moisture levels, they significantly prolong the life of transformer oil, which is crucial for seamless transformer functionality. Evidence shows that smart breathers outperform traditional breathers, maintaining oil purity by reducing water content by up to 85%. This enhancement in oil preservation ensures transformers operate efficiently and minimizes risks of premature failures, hence securing long-term operational reliability.

Smart breathers are engineered with a dual protection system that simultaneously filters out particles and absorbs moisture. This multifaceted approach ensures comprehensive protection against both particulate contamination and humidity-related issues. Compared to traditional systems, data indicates that smart breathers reduce contaminant levels by up to 70% while also maintaining lower humidity. This dual action not only extends the life of the transformer but also improves its overall performance, making smart breathers a superior choice for effective transformer management.

According to industry reports, the implementation of smart breathers can increase the lifespan of transformers by up to 40%. This extension is attributed to the consistent control of contaminants, resulting in less wear and tear on vital components. Through effective moisture and particle management, smart breathers help maintain the integrity of transformers, thus reducing the need for frequent replacements and ensuring more reliable energy distribution, ultimately benefiting both utility companies and end consumers.

The economic benefits of using smart breathers are noticeable through reduced maintenance costs. These breathers significantly decrease failures and downtime, leading to lower expenses for upkeep and repairs. Companies switching to smart breather systems have documented substantial savings, with some reporting maintenance cost reductions of over 50%. This shift not only enhances financial efficiency but also encourages the broader adoption of smart breather technologies across the industry, highlighting their long-term cost-saving potential.

Maintaining optimal conditions with smart breathers leads to a notable improvement in the operational efficiency of transformers. By ensuring cleaner operation and reducing energy consumption, smart breathers contribute to the sustainable management of electrical systems. Research demonstrates that transformers equipped with smart breathers can reduce energy usage by up to 30%, showcasing a strong correlation between enhanced breather performance and energy efficiency. This improvement supports the industry's drive towards more sustainable practices and reduced environmental impact in transformer operations.

The three-stage filtration process in smart breathers is a cutting-edge technology designed to enhance total contaminant removal. The first stage involves mechanical filtration, which sieves out larger particles and debris. This is followed by adsorption, where activated materials capture and hold smaller contaminants. Finally, the desiccation stage removes moisture from the air, thus preventing it from entering the transformer. This layered approach, with its combination of mechanical, adsorptive, and desiccant methods, provides a robust shield against contaminants compared to the single-layer systems found in traditional breathers. The superiority of smart breathers in performing these functions enhances transformer reliability and lifespan, making them a preferred choice in high-stake applications.

Smart breathers incorporate check valve technology to prevent moisture backflow—a critical feature for operations in humid environments. Check valves allow airflow only in one direction and seal out moisture poised to backtrack into the system, thus maintaining the dryness of the air entering the transformer. Evidence from diverse industry applications shows how this technology has been instrumental in safeguarding systems against environmental moisture. In particular, studies and case analyses highlight substantial improvements in contamination control across sectors that experience significant humidity fluctuations. This makes smart breathers indispensable in ensuring consistent operational conditions and extending the service life of equipment.

Real-time performance indicators integrated into smart breathers revolutionize maintenance practices by allowing continuous monitoring of the breathers' effectiveness. These indicators provide critical insights into the moisture levels and contaminant presence, enabling immediate adjustments to maintain optimal operational conditions. By preemptively alerting to potential issues, these technologies facilitate proactive maintenance strategies, significantly reducing system downtime. Evidence from industry practices corroborates that real-time data collection lowers maintenance and repair costs while ensuring uninterrupted operations. This ensures that operational challenges are swiftly addressed, fostering an environment of preventive maintenance where potential failures are mitigated before they escalate.

Ensuring the proper sizing of breathers according to cubic feet per minute (CFM) requirements is crucial for maximizing effectiveness. Correct sizing prevents system inefficiencies such as pressure imbalances or inadequate filtration. Most manufacturers provide detailed charts and guidelines to aid in selecting the appropriate breather size based on specific CFM requirements. These resources help users match breathers to their operational needs, leading to enhanced system performance and longevity by maintaining ideal airflow.

Retrofitting existing systems with smart breathers can present compatibility challenges, which is where adapter kits come into play. Adapter kits bridge the gap between older system designs and newer, smart breather models, ensuring seamless integration. Successful retrofit implementations often show enhanced performance and extended equipment lifespan. These kits are particularly useful in industries like manufacturing and construction, where transitioning to smart breathers can significantly boost efficiency and reduce maintenance downtime.

Monitoring silica gel saturation levels is vital to maintaining the efficiency of desiccant breathers. As the desiccant absorbs moisture, its color typically changes, indicating the need for replacement. Regular checks and maintenance schedules are recommended to avoid over-saturation, which can compromise breather efficacy. Implementing indicators for saturation levels ensures proactive maintenance, reducing the risk of system failure due to moisture ingress. This practice is a key factor in maintaining system reliability and performance over time.

Particle breathers are designed to filter out particulate contaminants, enhancing the efficiency and longevity of machinery by preventing harmful particles from entering the system.

Desiccant breathers absorb moisture from the air using desiccants like silica gel, maintaining low humidity levels and preventing moisture-induced issues such as corrosion.

Smart breathers offer superior moisture elimination, dual protection against particulates and humidity, extended transformer lifespan, reduced maintenance costs, and improved operational efficiency.

The three-stage filtration involves mechanical filtration, adsorption, and desiccation, providing a robust shield against contaminants to enhance transformer reliability.

Monitoring silica gel saturation levels ensures that desiccant breathers maintain their efficiency by indicating when a replacement is needed, preventing system failure due to moisture ingress.