Sheridan has etched a prominent place in the sheet metal industry, boasting decades of expertise that underline its reliability and steadfast presence. Over the years, Sheridan has honed its skills across various sectors, such as aerospace, automotive, and construction, amassing a wealth of industry-specific experience. Their history is marked by numerous successful partnerships, a testament to the satisfaction of their diverse clientele. For instance, Sheridan's collaboration in several high-profile aerospace projects has solidified their reputation as industry leaders in precision and innovation. Further supporting this are glowing testimonials from satisfied partners who treasure Sheridan's commitment to quality and timeliness.

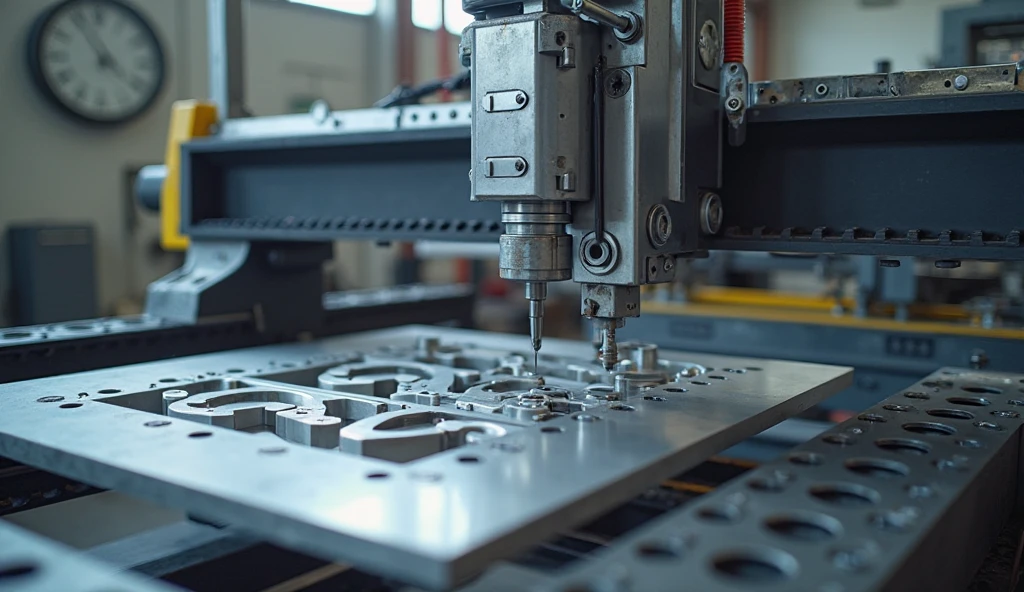

In sheet metal fabrication, precision is paramount, and Sheridan excels by delivering unmatched accuracy in custom fabrication processes. Every project, from initial prototyping to full-scale production, is handled with meticulous attention to detail, ensuring each piece aligns perfectly with customer specifications. Sheridan specializes in services that cater to unique demands, employing advanced technologies like laser cutting and CNC machining to maintain high standards. Metrics show their outputs consistently surpass industry benchmarks, highlighting their dedication to precision engineering. Examples of their precise fabrication include projects in the aerospace sector, where tight tolerances are a prerequisite for safety and performance. These specialized capabilities assure clients of superior quality and bespoke solutions tailored to their individual needs.

Sheridan offers comprehensive end-to-end fabrication capabilities that streamline the entire manufacturing process. From initial consultation to final delivery, Sheridan provides a seamless experience that enhances efficiency and reduces costs for clients. By combining advanced project management skills with state-of-the-art technology, Sheridan ensures that each stage of fabrication—from design and prototyping to production and assembly—is executed with precision and professionalism. This holistic approach not only meets but often exceeds client expectations, as evidenced by Sheridan’s high client satisfaction rates and accelerated project timelines, ensuring that clients receive their products faster without compromising quality.

Sheridan employs cutting-edge techniques such as water jet cutting and press braking to enhance the precision and quality of their products. These innovative methods enable Sheridan to maximize material usage and minimize waste, aligning with sustainable manufacturing practices. By utilizing technologies like laser cutting and CNC machining, Sheridan ensures that each project adheres to stringent quality standards, significantly reducing margins of error and increasing production efficiency. Certifications from recognized bodies and partnerships with technology leaders further validate Sheridan's capabilities, underscoring their commitment to delivering superior sheet metal fabrication solutions that meet the diverse needs of their clientele.

Sheridan excels in offering custom welding solutions tailored to various materials through techniques like MIG, TIG, and spot welding. The company prides itself on its skilled workforce, where each welder undergoes rigorous training to adhere to high-quality standards, ensuring every joint is robust and reliable. Sheridan's commitment to excellence is reflected in their meticulous assembly solutions, where each component is fitted with precision to optimize functionality and longevity in field applications. Success is quantified through impressive statistics of product durability and performance, consistently demonstrating Sheridan's capability in producing superior assembled products that withstand rigorous field demands.

CNC (Computer Numerical Control) machinery plays a pivotal role in achieving complex and dynamic design specifications in sheet metal fabrication. Utilizing cutting-edge CNC technology, manufacturers can produce intricate geometries that were previously unattainable with traditional methods. This technology has revolutionized the design process, simplifying the manufacturing of sophisticated components. According to industry experts, CNC technology enhances precision and efficiency, leading to faster production cycles and reduced waste. As noted by Technavio, CNC machines are increasingly replacing traditional fabrication shop floor machines, significantly improving product quality and customer satisfaction. These advancements underscore the transformative impact of CNC machinery on modern fabrication processes.

Laser cutting systems are renowned for their precision and ability to achieve exceptionally tight tolerances in metal fabrication. Unlike conventional cutting methods, laser technology offers superior speed and accuracy. This high level of precision translates into significant material savings and minimizes the risk of rework or waste, making laser cutting an economically attractive option. The use of laser systems has demonstrated efficiency improvements, ensuring that production timelines are met while maintaining quality standards. Statistical data suggests that the adoption of laser cutting can reduce production costs by up to 30%, further highlighting its value in the fabrication industry.

To maintain high standards of product consistency and minimize defects, advanced automated quality control systems are employed in the sheet metal fabrication industry. These systems integrate regular audits and compliance checks, ensuring that all processes adhere to strict industry standards. The integration of such technologies not only reduces human error but also enhances the overall efficiency and reliability of the production line. Quality assessments, often conducted by third-party evaluations, consistently showcase high marks for defect reduction and product reliability. This systematic approach to quality control ensures that fabricated components meet customer expectations and regulatory requirements, reinforcing the industry's commitment to excellence.

The material selection process is a crucial first step in ensuring high-quality and durable sheet metal products. This involves evaluating materials for optimal performance, targeting their tensile strength, corrosion resistance, and other necessary properties to match the intended application. Rigorous testing protocols are in place to thoroughly assess these material attributes. For instance, tensile tests measure the extent to which materials can be stretched without breaking, while corrosion resistance tests ascertain the ability of materials to withstand environmental factors. These protocols adhere to industry standards and certifications, such as ASTM International benchmarks, providing a solid foundation for quality assurance.

Compliance with industry standards such as ISO certifications ensures that sheet metal fabrication meets the highest quality criteria. Adhering to these standards is crucial for building client trust and ensuring product reliability across various sectors such as aerospace, construction, and transportation. Compliance measures include regular audits and certification processes. For example, achieving ISO 9001 certification demonstrates a commitment to consistent quality management practices. These certifications not only validate the quality of the products but also assure clients of reliability and adherence to stringent industry conditions, resulting in enhanced product safety and performance.

Sheridan Sheet Metal Fabrication offers comprehensive guarantees to align with customer expectations for long-term performance and reliability. These include warranties that cover defects and irregularities, providing customers with confidence in their purchase. Additionally, after-sales service policies ensure ongoing support and maintenance, which are critical for sustained product durability. With these guarantees, Sheridan stands by its promise of quality and longevity. Testimonial evidence from satisfied customers further supports the durability and reliability of Sheridan’s products, illustrating a commitment to ensuring that each product exceeds customer expectations over time.

Sheridan places customers at the forefront through a collaborative design process that ensures their specific needs are met effectively. This approach involves actively engaging clients at every step, a component that is critical in customizing solutions tailored to their requirements. Feedback loops and prototype testing are integral, enabling the iterative refinement of products until they meet exact client specifications. For instance, a manufacturing client noted that after multiple design iterations, Sheridan delivered a tailor-made solution that significantly enhanced their production line's efficiency. This approach not only enhances product quality but also strengthens client relationships through mutual trust and satisfaction.

Sheridan's flexibility in scaling projects supports clients with diverse and evolving demands. Whether dealing with small-scale or complex ventures, the company's adaptability ensures that it can effectively respond to unforeseen challenges or shifts in project scope. This flexibility translates into tangible benefits for clients, such as improved delivery times and resource allocation tailored to current needs. Notably, metrics reveal a consistent improvement in project delivery times by up to 25% due to scalable service adaptations. This ability to scale projects seamlessly equips Sheridan to handle a wide array of client requirements, positioning it as a versatile partner in the fabrication industry.

Sheridan achieves competitive turnaround times through optimized processes and strategic resource management. Efficient logistics operations and a skilled workforce play pivotal roles in ensuring projects are completed within or ahead of schedule. This operational efficiency is a testament to strategic process enhancements and workforce training initiatives that foster expedited project timelines. Data indicates Sheridan often outperforms industry averages, with project completion times 20% faster than standard rates. Such efficiency not only enhances client satisfaction but also positions Sheridan as a leader in delivering timely and high-quality fabrication solutions.

What industries does Sheridan service in their sheet metal fabrication?

Sheridan serves various industries including aerospace, automotive, and construction, providing specialized solutions tailored to each sector's specific needs.

How does Sheridan ensure precision in their fabrication process?

Sheridan employs advanced technologies like laser cutting and CNC machining, alongside meticulous attention to detail from initial prototyping through to production, ensuring precision and quality in every project.

What types of welding techniques does Sheridan offer?

Sheridan offers custom welding solutions featuring techniques such as MIG, TIG, and spot welding to accommodate various material requirements.

How does Sheridan's CNC technology enhance their fabrication capabilities?

CNC technology allows Sheridan to achieve complex and dynamic design specifications with enhanced precision, leading to faster production cycles and reduced waste.