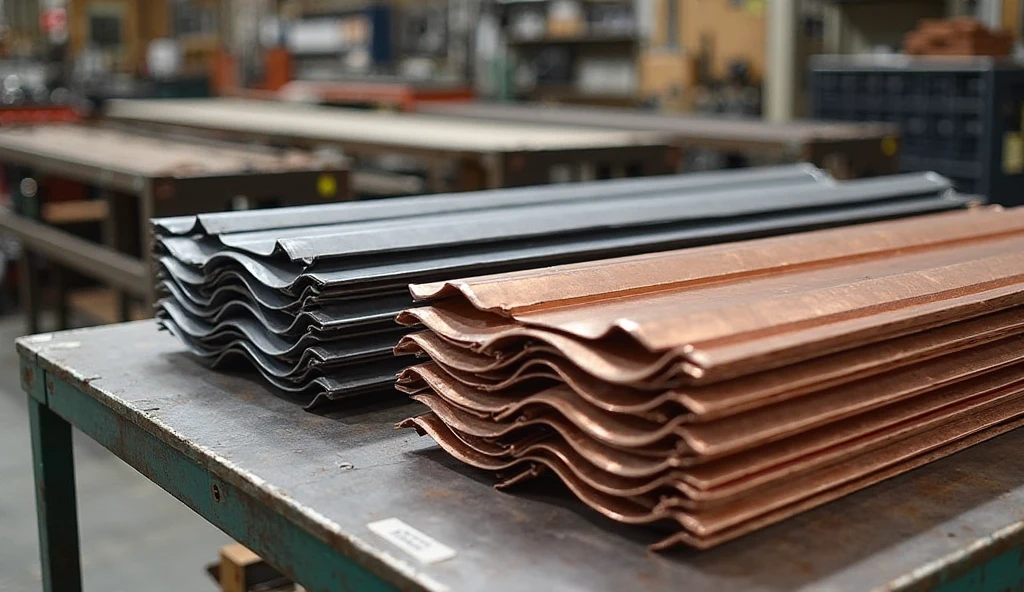

Sheet metal plays a pivotal role in modern roofing solutions due to its durability and aesthetic appeal. Homeowners and businesses increasingly turn to materials like aluminum and copper for their roofing needs due to these metals' long lifespan and minimal maintenance requirements. Aluminum is valued for its lightweight nature and resistance to corrosion, making it ideal for areas with a marine climate. Copper, on the other hand, is renowned for its distinctive appearance that develops a patina over time, adding character and elegance to any structure. These materials not only ensure longevity but also enhance visual appeal, contributing to ever-evolving architectural styles.

Beyond roofing, sheet metal is extensively used in various architectural applications, including decorative elements and energy efficiency improvements. Architects capitalize on its versatility, using it for cladding, facades, and intricate design flourishes. Additionally, the reflective properties of some metals play a role in improving energy efficiency by reducing heat absorption, thereby lowering cooling costs. Incorporating sheet metal into architectural designs not only elevates the aesthetic value of a building but also makes it more sustainable and energy-efficient.

Custom fabrication is integral for projects requiring unique sheet metal solutions tailored to client specifications. This process begins with an in-depth consultation to understand the client's needs, followed by the use of advanced CAD technology to design precise models of the required components. Once the design is finalized, CNC machining is employed to cut, bend, and shape the metal with high precision. This meticulous approach ensures that the final product meets exact standards and fits seamlessly into the project's overall blueprint.

The benefits of precision work in sheet metal fabrication extend beyond just quality. Precision helps in reducing material waste, which not only conserves resources but also minimizes costs. Furthermore, the accuracy of precision work speeds up project timelines as pieces fit correctly the first time, reducing the need for adjustments or do-overs. This efficient process not only saves money but also boosts client satisfaction by ensuring timely delivery of projects.

There are significant differences between residential and commercial sheet metal applications, primarily in terms of design and functionality. Residential projects often focus on aesthetics and personal customization, whereas commercial applications prioritize durability, scale, and compliance with industry standards. For instance, sheet metal roof designs in residential homes might emphasize visual appeal with decorative trims and custom accents, whereas commercial buildings will focus on function, often opting for robust solutions that withstand high traffic and harsh environmental conditions.

Case studies highlight specialized projects in both sectors, demonstrating the adaptability of sheet metal solutions. For instance, a residential project might showcase ornamental copper roofing and bespoke gutter systems, while a commercial project could feature industrial-grade metal facades and energy-efficient HVAC ductwork. When considering a supplier for sheet metal needs, factors such as project type, size, and budget are crucial. Choosing the right partner ensures that the specific demands of residential or commercial projects are met with expertise and precision.

Nimbus Roofing and Sheet Metal, LLC has carved a niche for itself as a reputable player in the Portland sheet metal industry. With a legacy of excellence, Nimbus Roofing has consistently provided top-tier roofing solutions and custom fabrication services. Their expertise is not only reflected in the quality of their projects but also in the positive feedback from their clients. A rich history in the industry combined with a commitment to customer satisfaction makes Nimbus Roofing a reliable choice for anyone seeking expert sheet metal suppliers in Portland. Through successful project outcomes, Nimbus Roofing continues to build its reputation as a trustworthy and skilled provider in the field.

Armadas Exterior LLC stands out as a premier expert in exterior metal applications with over 40 years of collective experience in the Portland area. The company excels in handling commercial projects and large-scale installations, offering a range of services that reflect their expertise in the field. A notable aspect of Armadas Exterior is their use of innovative techniques and materials, setting them apart in the competitive market of sheet metal suppliers. With a focus on reducing waste and enhancing project cohesion, Armadas Exterior’s services are designed to meet and exceed customer expectations, making them a leading choice for sheet metal projects.

Montavilla Sheet Metal & Stainless Steel Inc. specializes in offering high-quality stainless steel products, contributing significantly to its strong foothold in the Portland market. Their portfolio of key projects highlights excellent craftsmanship and attention to detail, qualities that define their reputation for superior delivery of products and services. Highlighting their dedication to customer service, Montavilla has succeeded in cultivating a loyal client base that trusts their expertise and commitment to satisfaction. This dedication ensures they remain at the forefront as esteemed stainless steel suppliers in Portland, consistently meeting the diverse needs of their clients.

Selecting a supplier with extensive knowledge of various sheet metal materials is critical for project success. A supplier with material expertise can provide valuable insights into choosing the right type of sheet metal for specific applications, whether it's for roofing or decorative elements. It's essential to look for suppliers who hold key certifications and standards, such as ISO or ASTM, which indicate reliability and adherence to industry best practices. For instance, specialized materials like stainless steel are ideal for applications requiring durability and resistance to corrosion, making them suitable for both functional and aesthetic purposes.

When it comes to investing in sheet metal projects, understanding warranty offerings and service guarantees can significantly influence decision-making. Typically, warranties cover not only the material's longevity but also potential defects that could compromise structural integrity. Such guarantees offer peace of mind, ensuring customers that their investment is protected over time. Leading suppliers in the Portland area often exceed basic expectations by providing comprehensive service guarantees that reflect their commitment to customer satisfaction and quality assurance. Comparing these offerings can help businesses select suppliers that align with their needs and project scopes, ultimately enhancing long-term collaboration.

A supplier's local experience is invaluable in understanding regional building codes and climate challenges, which can greatly affect the performance of sheet metal installations. Local suppliers are often more adept at navigating these nuances, ensuring compliance and optimal longevity of projects. Reviewing a supplier's project portfolio can provide insights into their versatility and expertise across various sheet metal applications. Potential clients are encouraged to evaluate past work and client feedback, which are instrumental in assessing the supplier's capability to handle similar projects. This assessment not only aids in making informed decisions but also builds confidence in the supplier's ability to meet specific project requirements.

In-house manufacturing capabilities play a crucial role in enhancing efficiency and maintaining quality within Portland's sheet metal industry. By keeping production processes internal, suppliers can have greater control over quality, ensure faster adjustments to manufacturing lines, and reduce dependency on external sources. Innovations like precision technologies are revolutionizing production methods. For instance, laser cutting and robotic welding have greatly increased the precision and adaptability of sheet metal products. These technologies not only elevate the quality of the final output but also significantly cut down costs attributed to waste and errors. Embracing such advancements enables suppliers to reduce overall project turnaround times, which is beneficial for meeting tight deadlines and improving client satisfaction. These capabilities make local suppliers more competitive and offer added value to clients seeking timely, high-quality solutions.

Portland's sheet metal suppliers are at the forefront of adopting sustainable practices that emphasize environmental stewardship. This trend includes a concerted effort toward recycling and reducing waste in production processes, which not only minimizes environmental impact but also leads to cost savings. Additionally, innovations in materials have led to the development of eco-friendly alloys and finishes that support sustainability goals. These advanced materials reduce resource usage and facilitate longer-lasting products, aligning with global environmental initiatives. Case studies of local suppliers highlight their leadership in green initiatives, showcasing Portland's commitment to environmentally conscious practices. By adopting these sustainable strategies, suppliers are not only preserving natural resources but also positioning themselves as pioneers in green sheet metal production within the industry.

Aluminum and copper are ideal due to their durability, resistance to corrosion, and aesthetic appeal. Aluminum is lightweight and suitable for marine climates, while copper develops a patina over time, adding elegance.

Custom fabrication ensures precise fitting and reduces material waste, cutting costs and speeding up project timelines. It allows tailored solutions to client specifications, boosting satisfaction.

Consider suppliers' material expertise, industry certifications, warranty offerings, local experience, and project portfolio to ensure alignment with your project needs and expectations.